sizzling plate induction

In addition to its functional benefits, the cast iron cookware in this set also tells a story. Cast iron has been used for centuries, cherished for its durability and versatility. Over time, each piece develops a natural non-stick surface, enhanced by proper seasoning, which only adds to its character. Cooking with cast iron is not just about preparing food; it’s about creating memories, sharing meals with friends and family, and connecting with nature.

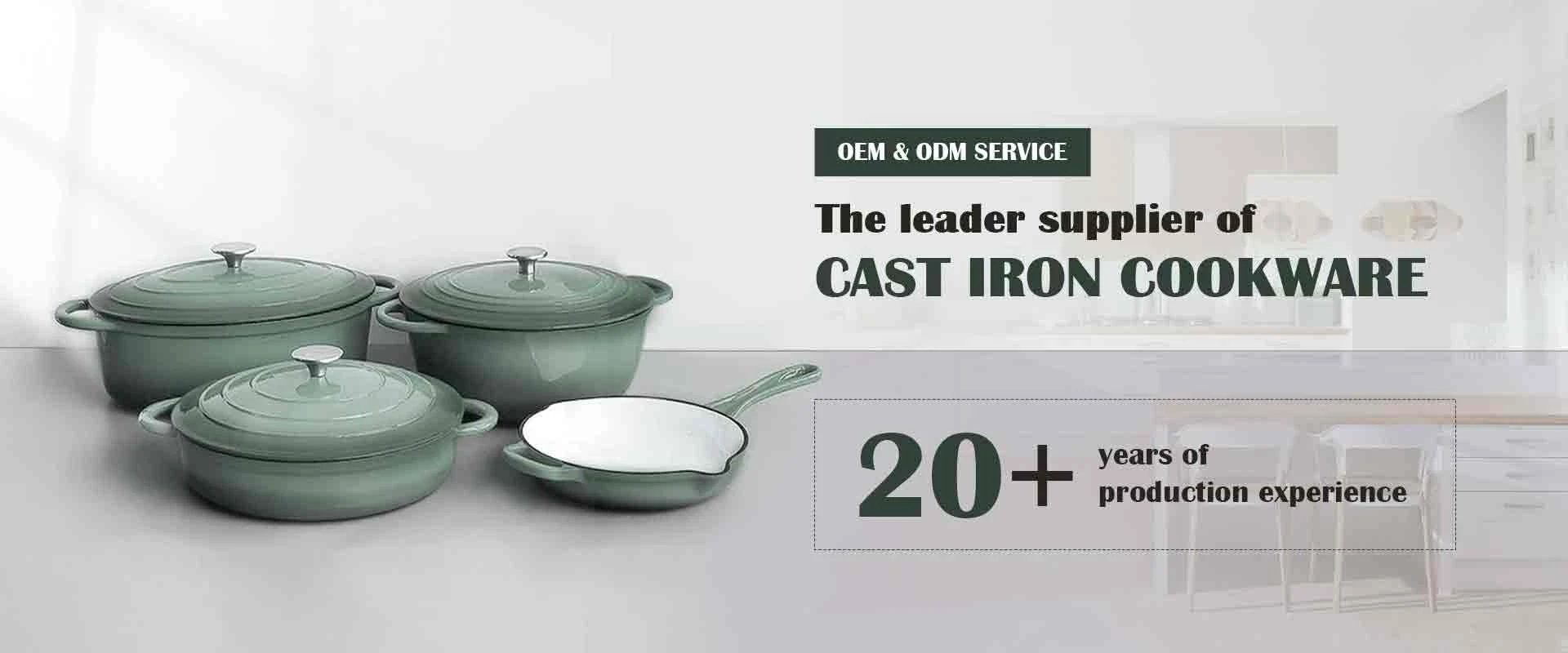

A enamel cast iron cookware set is ideal for those who want to enjoy the benefits of cast iron cooking without the need for regular seasoning. The enamel coating provides a non-stick surface that’s easy to clean, while also being resistant to staining and odors. This makes it an excellent choice for preparing a variety of dishes, from delicate sauces to hearty casseroles.

6. Cool and Enjoy

Another benefit of using a cast iron griddle on an electric stove is its durability. Cast iron can withstand high temperatures, making it suitable for a wide range of cooking methods, including searing and sautéing. While electric stovetops may take a bit longer to reach the desired temperature compared to gas, once they do, the heavy cast iron griddle will hold that heat well. This characteristic is particularly advantageous for recipes requiring searing or browning, where a steady, high heat is necessary.

Health Considerations

The Sizzler Plate A Big Hit for Hunger Pangs

Conclusion

หนึ่งในเมนูที่เป็นที่นิยมในการใช้เตาหม้อดัตช์คือ สตูว์ (Stew) ซึ่งเป็นการตุ๋นเนื้อสัตว์และผักในน้ำซุปหรือซอส เป็นเวลานาน จนเนื้อสัตว์นุ่มละลายในปากและรสชาติกลมกล่อม การปรุงอาหารในเตาหม้อดัตช์จะช่วยให้ได้รสชาติที่กลมกล่อมและมีความหอมเหมือนได้รับการปรุงโดยเชฟมืออาชีพ

Een ander belangrijk voordeel van geëmailleerd gietijzer is de duurzaamheid. In tegenstelling tot gewone gietijzeren pannen, die een beetje onderhoud vergen om roestvorming te voorkomen, biedt de emaille-laag een extra bescherming. Dit betekent dat je je geen zorgen hoeft te maken over het inbranden of het onderhoud van de pan. Je kunt het gewoon in de vaatwasser doen, hoewel handwas met warm water en een zachte spons wordt aanbevolen om de levensduur te verlengen.

b. Industry Consultants:

Wear Factors: Liners experience wear from the continuous contact with the slurry.

b. Industry Consultants:

The effectiveness of slurry transport using centrifugal pumps largely depends on the pump’s ability to handle abrasive and viscous materials. Performance testing for slurry transport applications involves assessing how well the horizontal centrifugal slurry pump can move slurry without significant wear or loss of efficiency. This testing includes monitoring the pump’s performance over time, particularly under harsh operating conditions, to ensure that the centrifugal slurry pump can withstand the rigors of slurry transport. Evaluating the pump’s performance in this context helps identify potential issues before they lead to system failures, ensuring that the AH Slurry Pump parts remain in good condition and continue to operate efficiently.

- Choose materials that can withstand the slurry's abrasiveness and corrosiveness. Common materials include high-chrome alloys, stainless steel, and rubber linings.

The pump casing encases the impeller and provides a pathway for the slurry to flow. It is structured to withstand high-pressure conditions and is often made from durable materials such as cast iron or high chromium content alloys. The casing must also be designed to minimize wear caused by the abrasive nature of the slurry, making material selection critical for long-term performance.

a. Manufacturer’s Support:

- Flow Rate: Determine the required flow rate (typically in cubic meters per hour or gallons per minute).

- Review the performance curves for the selected pump models to ensure they meet your flow rate and head requirements.

Materials: Materials used for shaft sleeves include hardened stainless steel and ceramic-coated materials.

- Head: Calculate the total head required (static head plus friction losses).

Types:

Function: The expeller and expeller rings work together to reduce the pressure and minimize leakage from the pump.

- Choose materials that can withstand the slurry's abrasiveness and corrosiveness. Common materials include high-chrome alloys, stainless steel, and rubber linings.

SPR slurry pumps are specifically designed for handling slurry in applications where high liquid levels are a concern. These pumps are engineered to operate efficiently in environments where the pump must remain submerged for extended periods. The vertical design of SPR slurry pumps allows them to function effectively in deep pits and sumps, where other pump types might struggle. By optimizing the design to handle high liquid levels, SPR slurry pumps provide reliable performance in challenging conditions, ensuring that slurry is effectively managed and transported, even in the most demanding deep pit applications.